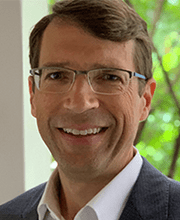

J. Russ Snider joined Tronox in April 2019 as part of the Cristal acquisition. He leads a team of Marketing professionals and is responsible for global marketing strategy, margin improvement, segment portfolio optimization, new product direction, product promotions and branding. He has 25 years of titanium dioxide experience including international assignments in Switzerland and the Netherlands. He previously held roles in Sales, Sales and Operations Planning, R&D and Engineering. Mr. Snider holds a B.S. in Chemical Engineering from the University of Tennessee.

Reg Adams compiles and edits two periodicals, the monthly Focus on Pigments and the quarterly TiO2 Worldwide Update, both of which were launched in 1993. He is also the author or co-author of nine books on the topics of the titanium value-chain, the carbon black industry and iron oxide pigments. In addition, he often carries out consultancy assignments and serves as an expert witness in matters of commercial litigation. He is a Forum Manager and regular contributor for the TiO2 Group on the Linked-In platform and he has been a speaker or chairman at more than 60 specialist conferences around the world covering paints, pigments or minerals. Prior to establishing Artikol, his own consultancy, database and publishing business, he studied Chemistry & Economics at Birmingham University, gained a post-graduate business degree from Bristol University and then worked for Amalgamated Metal (a mining finance house), BSC (publishers, specialising in the fertiliser and chemical industries) and Metra (management consultants, advising on pharmaceuticals and specialty chemicals).

David Wawer has served as Executive Director of the Color Pigments Manufacturers Association (CPMA) since 2014. As Executive Director, Mr. Wawer is the spokesperson for the association, providing industry economic and regulatory analysis to industry trade press, public policy media organizations, NGO’s, government officials, and other public stakeholders.

CPMA is the only U.S.-based trade association dedicated to the color pigments sector, serving as the industry voice on public policy issues pertaining to the environment, health, safety and trade. CPMA provides technical and scientific analysis on emerging laws and regulations impacting the color pigments industry and its key markets in North America, including printing inks, paints and coatings, plastics, agriculture, cosmetics, personal care, packaging and others. As part of its key initiatives, CPMA is working with its members and value chain industry partners to develop a sustainability framework for the color pigments sector.

Franz holds a PhD in aerosol science from ETH Zurich. During several years of analysing airborne nanoparticles in the laboratory, he developed an analysis concept to measure the mass of single particles. As a co-founder and CEO of femtoG, a Swiss start-up, he set out to revolutionize the analysis of pigment particles and nanostructured materials.

With a career spanning multiple commodities, Aaron Bertram, Manager Product Development, began his career with Rio Tinto. Over his 20+ years in mining, Aaron initially focused on the technical aspects of orebody knowledge and regulatory compliance. He then expanded into broader commercial and strategy roles, leveraging his technical knowledge to guide investment decisions through technical and business evaluations. In early 2022, Aaron joined Iluka, where he now oversees technical marketing for TiO2 feedstock products.

Aaron holds a Master of Science Geology from McMaster University.

Gerry Colamarino is currently the Managing Director of TiPMC Solutions LLC, which he founded in 2014.. He has over 30 years of international experience within the chemical, mining, and energy industries, having had multiple professional and leadership positions within the former DuPont Titanium Technologies (Chemours), Iluka Resources, and Bloom Energy.

TiPMC is a recognized thought leader and independent resource for all subjects pertaining to the TiO2 value chain, with a strong focus on TiO2 pigments and Mineral Sands. TiPMC employs a unique network of industry and functional experts, providing boutique consulting and advisory services, industry publications, and data services to financial institutions and industry participants world-wide.

Gerry is a graduate of Rutgers University, earning a B.S. in Mechanical Engineering. He currently resides with his family in Nashville, TN.

Julie has 22 years’ experience in the titanium dioxide pigment manufacturing industry and 28 years in the chemical industry. She is currently Marketing Director at LB Group (formerly known as Lomon Billions Group), the world’s No.1 manufacturer of titanium dioxide (TiO2) pigments. Prior to joining LB Group, Julie spent 14 years with Huntsman in its Pigments division (now Venator), where she held various positions within Marketing and R&D. Julie studied at Heriot-Watt University, UK, for her Chemistry degree and holds a Professional Diploma in Marketing from the Chartered Institute of Marketing.

Prior to co-founding Alembic Global Advisors Hassan was a Managing Director and Global Sector Head for Chemicals Research at HSBC. Previously, Hassan has worked as a senior buy-side research analyst covering the materials space at Brown Brothers Harriman, a senior sell-side research analyst covering the chemical space at Sanford Bernstein, a strategy consultant at the Mitchell Madison Group and a process engineer at Imperial Chemical Industries (ICI). Hassan has won several accolades in research having been ranked #1 Middle East and North Africa analyst across all sectors by Extel consecutively for the last four years; #1 US stock picker by FT/Starmine in 2008 and Best Up and Comer in the US chemical sector by Institutional Investor in 2006 and 2008. He received a bachelor’s degree with honors in chemical engineering from London University and an MS degree in operations research from Columbia University.

Andreas Reitz is a Sales Manager at Haver & Boecker OHG, where he specializes in technical sales for the specialty chemicals sector. He supports clients in optimizing their production processes through customized, efficient, and sustainable packaging solutions. His expertise lies in the handling and packaging of fine powders such as titanium dioxide, with a strong focus on cleanliness, operational efficiency, and safety.

Since joining Haver & Boecker in 2014, he has held various roles across technical operations and project management until 2020 joining technical sales.

He holds a Bachelor of Engineering in Mechanical Engineering from the South Westphalia University of Applied Sciences and is currently pursuing an MBA in Management for Engineering Sciences at Bielefeld University of Applied Sciences.

At the TiO₂ World Summit, Mr. Reitz will share insights into the latest developments in packaging technologies for TiO₂, focusing on how engineering-driven solutions can improve product quality, safety, and overall process performance.

.jpg?ext=.jpg)

John Elder is a seasoned leader in the global mining and minerals industry with over three decades of experience. He is the Principal of John Elder Consulting, specializing in the Rare Earths and TiO2 value chains. Before founding his consultancy in 2022, John held pivotal roles at Hatch, a leading global engineering and consulting firm. As the USA Director for Mining and Metals, he led major initiatives in copper, gold, and lithium projects. He also served as Global Director of Rare Earths, as well as Global Director of Diamonds, Borates, and Mineral Sands/TiO2, providing strategic oversight and executive sponsorship for complex, multi- regional projects. Prior to his time at Hatch, John was President of Outotec’s (now Metso) Physical Separation Division, where he managed a global portfolio of products and projects. Earlier in his career, he served as the Exploration and Development Manager at RGC (now Iluka Resources), leading commercial discoveries and developments across multiple countries.

I am a collaborative leader with business intelligence, forecasting, merger and acquisition, and financial reporting and analysis expertise. I am highly skilled in interpreting market and business data to provide actionable forecasts on monthly, annual, and long term basis. I have several years of experience at facilitating monthly, quarterly and annual closing activities, including preparation of financial statements.

Coming soon.

Steve Forrest serves as the Global Director of Marketing for Tronox, one of the world’s leading manufacturers of titanium dioxide (TiO2) pigments and a leading producer of titanium chemicals. Tronox is also the world’s leading vertically integrated supplier. Tronox provides ultrafine TiO2 products and zircon as well as rare earth products.

In his role, Steve leads the global marketing team, responsible for Tronox’s TiO2 product brand: TiONA® driving strategic development, innovation, collaboration, product-line and market segmentation.

Steve has spent almost three decades travelling throughout Asia-Pacific, working with customers on titanium dioxide related issues. He has written and delivered numerous papers on pigment-related topics at international conferences and co-edited educational texts on titanium dioxide pigments and the titanium pigment industry. He is currently based in Western Australia at Tronox’s Bunbury TiO2 site.

Lisa Clapp is the Vice President of Colors Technology at Sun Chemical Corporation with responsibility for research and development of pigments and pigment preparations.

Lisa did her undergraduate work in chemistry at Ball State University and received her Master’s of Science degree in Physical Chemistry from the University of North Carolina- Chapel Hill.

Lisa has worked for Sun Chemical for 23 years, where she has held numerous positions, including physical chemist, group leader, Six Sigma Black Belt, Design for Six Sigma Leader, and project manager covering a wide range of Sun Chemical pigment and preparation products.