Speakers include:

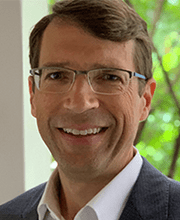

J. Russ Snider joined Tronox in April 2019 as part of the Cristal acquisition. He leads a team of Marketing professionals and is responsible for global marketing strategy, margin improvement, segment portfolio optimization, new product direction, product promotions and branding. He has 25 years of titanium dioxide experience including international assignments in Switzerland and the Netherlands. He previously held roles in Sales, Sales and Operations Planning, R&D and Engineering. Mr. Snider holds a B.S. in Chemical Engineering from the University of Tennessee.

Reg Adams compiles and edits two periodicals, the monthly Focus on Pigments and the quarterly TiO2 Worldwide Update, both of which were launched in 1993. He is also the author or co-author of nine books on the topics of the titanium value-chain, the carbon black industry and iron oxide pigments. In addition, he often carries out consultancy assignments and serves as an expert witness in matters of commercial litigation. He is a Forum Manager and regular contributor for the TiO2 Group on the Linked-In platform and he has been a speaker or chairman at more than 60 specialist conferences around the world covering paints, pigments or minerals. Prior to establishing Artikol, his own consultancy, database and publishing business, he studied Chemistry & Economics at Birmingham University, gained a post-graduate business degree from Bristol University and then worked for Amalgamated Metal (a mining finance house), BSC (publishers, specialising in the fertiliser and chemical industries) and Metra (management consultants, advising on pharmaceuticals and specialty chemicals).

David Wawer has served as Executive Director of the Color Pigments Manufacturers Association (CPMA) since 2014. As Executive Director, Mr. Wawer is the spokesperson for the association, providing industry economic and regulatory analysis to industry trade press, public policy media organizations, NGO’s, government officials, and other public stakeholders.

CPMA is the only U.S.-based trade association dedicated to the color pigments sector, serving as the industry voice on public policy issues pertaining to the environment, health, safety and trade. CPMA provides technical and scientific analysis on emerging laws and regulations impacting the color pigments industry and its key markets in North America, including printing inks, paints and coatings, plastics, agriculture, cosmetics, personal care, packaging and others. As part of its key initiatives, CPMA is working with its members and value chain industry partners to develop a sustainability framework for the color pigments sector.

Franz holds a PhD in aerosol science from ETH Zurich. During several years of analysing airborne nanoparticles in the laboratory, he developed an analysis concept to measure the mass of single particles. As a co-founder and CEO of femtoG, a Swiss start-up, he set out to revolutionize the analysis of pigment particles and nanostructured materials.

Eldon has been with PPG since 1999 and currently is a Senior Research Associate in the Optical Physics Group at the Coatings Innovation Center in Allison Park, Pennsylvania, USA. Some of the areas in which he has worked at PPG include: Andaro® nano-pigment dispersions, leading to commercialization of highly chromatic and transparent solventborne, waterborne, powder, and electro-deposition coatings; more efficient use of TiO2 through computational and experimental studies; solar heat management coatings; structural color pigments; and coatings to enable proper function of advanced driver-assistance systems, including lidar and radar compatible color technologies.

Eldon received Bachelor and Master of Science degrees in Physics from Brigham Young University, where he did research in characterizing fullerene materials at high pressures. He also received a Master of Science degree in Colloids, Polymers, and Surfaces, and a Ph.D. in Physics from Carnegie Mellon University, where he researched the wetting characteristics of heterogeneous surfaces. Previous to starting at PPG, Eldon conducted post-doctoral research at the University of Pittsburgh, where he analyzed pattern formation in anisotropic fluid flow.

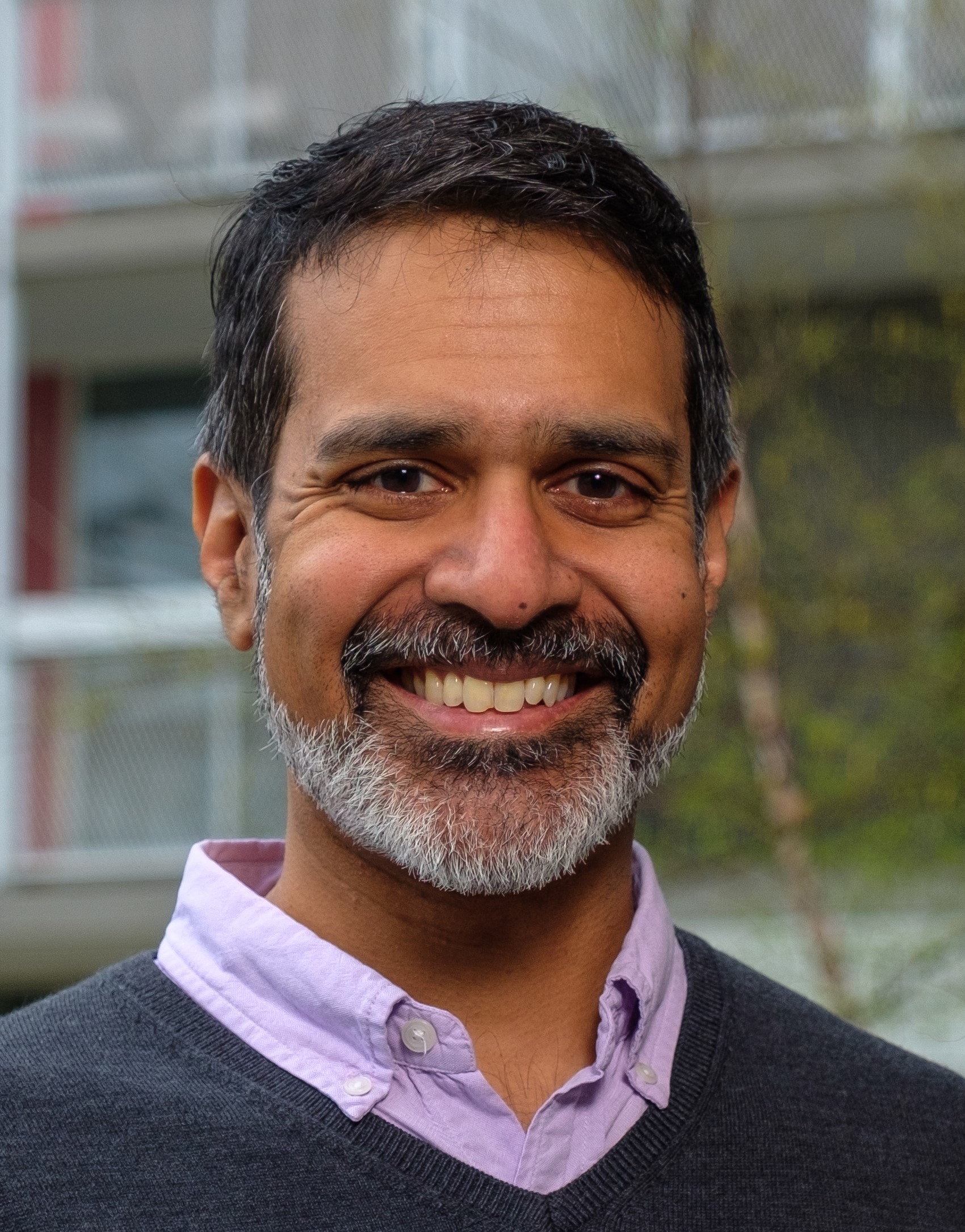

Vinothan N. Manoharan is a Professor in the School of Engineering and Applied Sciences and the Department of Physics at Harvard University. His research focuses on understanding how living systems build complex structures, and how to replicate those structures in synthetic systems.

Daeyeon Lee is the Russell Pearce and Elizabeth Crimian Heuer Professor of Chemical and Biomolecular Engineering at the University of Pennsylvania. He received his BS in Chemical Engineering from Seoul National University and his PhD in Chemical Engineering from MIT. His research explores the interactions of soft materials at interfaces, with the goal of developing innovative processes and structures with applications in healthcare and environmental sustainability. He has been recognized for excellence in research with several awards, including the 2010 Victor K. LaMer Award, an NSF CAREER Award, the 2013 3M Nontenured Faculty Award, the 2013 AIChE NSEF Young Investigator Award, the 2014 Unilever Award for Young Investigators in Colloid and Surface Science, the 2017 Soft Matter Lectureship Award, and the 2023 Outstanding Achievement Award in Nanoscience. He has also been acknowledged for his contributions to education with awards such as the Penn CBE Distinguished Teaching Awards and the 2017 S. Reid Warren, Jr. Award, and he held the Evan C. Thompson Endowed Term Chair for Excellence in Teaching from 2020 to 2023. Since 2024, Daeyeon has served as Director of the NSF Artificial Intelligence-Driven RNA BioFoundry (AIRFoundry), a groundbreaking platform that integrates artificial intelligence, automation and microfluidics to advance RNA design, synthesis, and delivery for a broad range of applications.

Coming soon.

Andre Bendo is a Technical Industry Manager with Color Materials. Based in Philadelphia, he has over 30 years of experience related to pigments and coating applications. Andre has gained an interesting perspective on pigments through a variety of positions in Research & Development, Quality, Production, Technical Service, Marketing and now Business Development. Currently supporting customers from all Coatings applications, his core passion is Automotive and color expression. Andre holds a Bachelor of Science degree in Chemical Engineering from the University of Delaware (USA).

Scott spent his career building early stage biotechnology companies. This includes venture backed Valcent Products Inc, Global Green Solutions and Solix Biosystems. At these startups he developed experience in product development, technology deployment and business development. At Living Ink, Scott drives strategic planning, fundraising and partnerships. He earned his B.S. from Michigan State University and his Ph.D from Colorado State University, where he as an NSF-GRFP Fellow and NSF-IGERT Bioenergy Fellow. During these bioenergy fellowships he implemented multidisciplinary approaches in policy, economics and environmental assessment.

Jane Palmer is the founder and CEO of Nature Coatings Inc. She has spent the last 20+ years in pigments and dyes. Before Nature Coatings she founded a dye house in Los Angeles called Noon Design Studio, the first modern-day dye house to use only plant and insect based dyes for textiles. She grew that business to over 100 repeat customers and sold it to an existing customer in 2015. In 2016, Ms. Palmer received a competitive and prestigious award from the US National Science Foundation to develop a high-performing and cost-competitive bio pigment. She incorporated Nature Coatings in early 2018 and launched the first 100% biobased pigment dispersion on the market in 2021. Since then she has raised millions of dollars to fund the growth of the company, including building a factory in the southeast US, developing multiple bio based pigment products, expanding market reach into paint, cosmetics, automotive, industrial coatings and more, and growing the team. Ms. Palmer holds two patents, a summa cum laude Bachelors of Arts degree and Masters of Arts degree.

Mark Ryan is the Market and Product Manager for the Shepherd Color Company where he has worked since 1999. Mark is responsible for market and product development for key technologies such as:

• Arctic IR reflective pigments

• the NTP Yellow and RTZ Orange

• YInMn Blue,

• Dynamix easily-dispersed pigments

• Shepherd Color’s highly-durable and heat-stable standard pigments.

Mark has presented and been published around the world on the use of these problem-solving pigments for paints, coatings, plastics and other materials. He has been quoted in Bloomberg and the Harvard Business Review and he was profiled by the Cooper Hewitt Smithsonian Design Museum. Mark has twice won the SPE-CAD RETEC Best Paper Award. He has been involved in high performance materials for over 30 years and has a bachelor’s degree in chemistry from Saint Louis University and an MBA from the University of Missouri at St. Louis. He is a SPE-CAD board member. His favorite color is blue.

Thomas Meeker has worked in the Technical Arts industry since completing his studies in Architecture at the School of the Art Institute of Chicago in 2009, where he was first introduced to 3D modeling and animation software. As 3D Solution Architect, Thomas supports X-Rite’s Appearance Portfolio as Product Champion for North America. Helping organizations expand their color maturity to include color and appearance workflows in virtual prototyping.

Lisa Clapp is the Vice President of Colors Technology at Sun Chemical Corporation with responsibility for research and development of pigments and pigment preparations.

Lisa did her undergraduate work in chemistry at Ball State University and received her Master’s of Science degree in Physical Chemistry from the University of North Carolina- Chapel Hill.

Lisa has worked for Sun Chemical for 23 years, where she has held numerous positions, including physical chemist, group leader, Six Sigma Black Belt, Design for Six Sigma Leader, and project manager covering a wide range of Sun Chemical pigment and preparation products.